GD & T / FEA

About Course

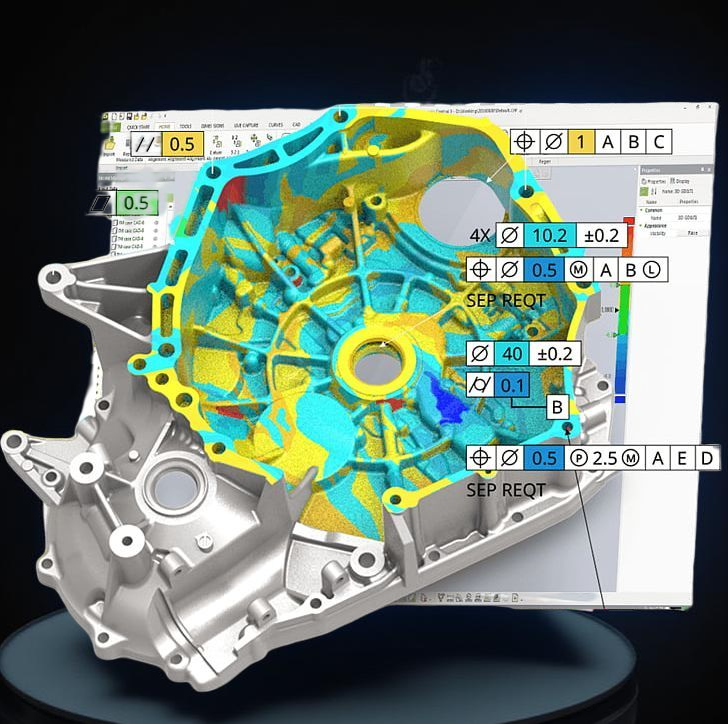

The GD&T / FEA course is designed to help students understand how design accuracy and analytical validation come together in modern product development.

The GD&T (Geometric Dimensioning & Tolerancing) section focuses on interpreting and applying international standards (ASME Y14.5) for engineering drawings, enabling precise communication between design, manufacturing, and inspection teams.

The FEA (Finite Element Analysis) section focuses on theoretical and simulation-based analysis using NX CAE and SolidWorks Simulation, empowering students to predict product performance, strength, and durability virtually before manufacturing.

This course is fully classroom + computer lab based, emphasizing design understanding, tolerance application, and simulation interpretation.

Course Objectives

Pre-requisites

The course is ideal for individuals with:

Basic knowledge of engineering drawings and 3D modeling

Prior exposure to any CAD software (AutoCAD, CATIA, NX, or SolidWorks)

No prior FEA or GD&T experience required

Duration

Total Duration: 2 Months

▸ 1 Month of GD&T Theory and Application

▸ 1 Month of FEA Tools and Analysis ProjectsDaily Duration: 8 Hours per day

Class Recordings: Available for self-paced revision

What You'll Learn

✅ Fundamentals of GD&T symbols, datums, and feature control frames

✅ Applying tolerances to 2D drawings and 3D models

✅ Understanding dimensional variation and its impact on assembly fit

✅ Introduction to Finite Element Analysis (FEA) theory

✅ Static, modal, and thermal analysis fundamentals

✅ Performing FEA simulations in NX CAE and SolidWorks Simulation

✅ Reading and interpreting simulation results (stress, strain, deformation)

Who Can Join

Diploma and B.Tech Mechanical, Production, or Automotive students

CAD/CAM-trained learners seeking design validation knowledge

Engineers preparing for design or CAE roles in manufacturing

Training Phases

Objective: Understand the importance of dimensional accuracy in design and manufacturing.

Topics:

Why GD&T is used in engineering

Conventional vs GD&T tolerancing

ASME Y14.5 standard overview

Introduction to symbols, feature control frames, and datum system

Activity: Analyze sample drawing with basic tolerances.

Objective: Learn to define datums and apply geometric controls.

Topics:

Primary, secondary, and tertiary datums

Feature control frames and modifiers

Form, orientation, location, and runout symbols

Activity: Interpret a detailed engineering drawing with full GD&T notation.

Objective: Understand the relationship between tolerances, limits, and manufacturing fit.

Topics:

Types of fits (clearance, interference, transition)

Tolerance stack-up and dimensional variation

Drawing application and inspection references

Activity: Calculate and visualize tolerance stack-ups.

Objective: Apply GD&T annotations digitally in CAD drawings.

Topics:

Applying GD&T in 2D drawings (NX Drafting & SolidWorks Drawing)

Annotating 3D models using PMI (Product Manufacturing Information)

Standards for inspection and documentation

Activity: Create a GD&T-annotated 3D model and export drawing.

Objective: Build conceptual understanding of structural analysis and simulation workflow.

Topics:

Basics of stress, strain, and deformation

Discretization and meshing concept

Types of analysis: static, modal, thermal

Load, boundary condition, and material definition

Activity: Case study on simple cantilever beam stress behavior.

Objective: Learn FEA fundamentals using NX Simulation Environment.

Topics:

Setting up analysis model in NX

Meshing and refining mesh density

Applying loads, constraints, and materials

Running static structural analysis and viewing results

Lab: Perform first simulation on a bracket or mechanical component.

Objective: Explore design validation through integrated SolidWorks Simulation.

Topics:

Model import and setup in Simulation tab

Defining mesh control and connection types

Performing static and thermal analysis

Comparing results with NX simulation for validation

Lab: Analyze deformation and stress on a 3D model (e.g., lever arm).

Objective: Relate design tolerance application with simulation performance.

Topics:

How tolerance affects assembly stiffness and load paths

Real-world correlation between GD&T and stress zones

Discussion: tolerance optimization vs strength analysis

Activity: Adjust tolerance and observe its impact on deformation in simulation.

Objective: Apply GD&T and FEA concepts to a single mechanical part.

Project Scope:

Annotate a component with GD&T

Perform NX and SolidWorks simulations under different loading

Compare results and generate reports

Objective: Conduct a full product validation from drawing to analysis.

Project Includes:

Create 2D drawing with GD&T

Model in 3D CAD

Run FEA simulation (NX or SolidWorks)

Submit results with graphical plots and design conclusions