CNC PROGRAMMING

About Course

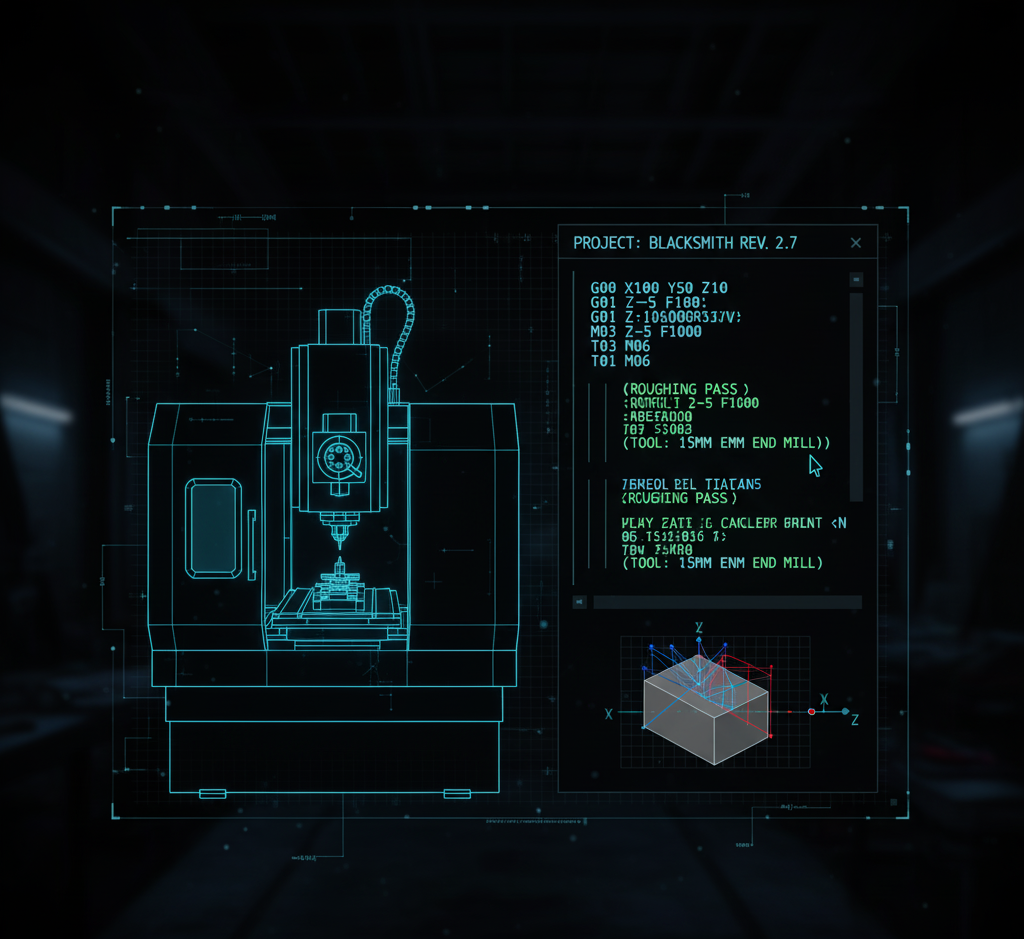

The CNC Programming (Manual Programming for Lathe & Milling using FANUC Language) course is designed to give students a complete understanding of Computer Numerical Control (CNC) machine operations and manual part programming. This course focuses on programming lathe and milling machines using FANUC controller codes (G & M codes) — the most widely used CNC language in the manufacturing industry.

Learners will study both theoretical & simulation based machine practice, including coordinate systems, tool offsets, cutting parameters, and code optimization. Through real part simulation sessions, students will learn how to write, verify, and execute CNC programs for precision manufacturing. By the end of the course, learners will be confident in developing and running manual CNC programs independently on FANUC-based machines.

Course Objectives

Pre-requisites

This course is ideal for learners who have:

Basic understanding of machining operations and machine tools.

Knowledge of technical drawing or manufacturing fundamentals is helpful.

Duration

Duration: 2 months

Class Duration: 8 Hours per day

Includes recorded sessions, software tutorials, and project guidance

What You'll Learn

By completing this course, you’ll be able to:

Understand CNC machine structure, components, and working principles.

Write manual G & M code programs for both lathe and milling machines.

Set up tool offsets, coordinate systems, and reference points.

Execute, test, and troubleshoot CNC programs safely.

Perform program verification and dry run checks in simulations.

Apply machining knowledge for industrial production and precision part manufacturing.

Who Can Join

This course is ideal for:

ITI, Diploma, and B.Tech (Mechanical) students interested in CNC manufacturing.

Machine operators or fresh graduates looking to upgrade to CNC programming roles.

Professionals and entrepreneurs aiming to enter or expand in precision engineering and production sectors.

Training Phases

Objective: Learn the basic principles, importance, and applications of CNC systems.

Includes:

Evolution of NC → CNC → Automation systems

CNC definition, purpose & industrial applications

CNC vs conventional machines

CNC system structure (bed, spindle, control, feedback)

Simulation Practice:

Identifying parts of CNC machines in simulator

Objective: Understand machine axis directions, coordinate systems, and motion control.

Includes:

Axis notation (X, Y, Z; U, W)

Positive and negative movement conventions

Absolute vs Incremental coordinates

Graph plotting (P0, P1, etc.)

FANUC system orientation

Simulation Practice:

Plot coordinates graphically and observe direction flow

Objective: Learn to operate CNC control panel, modes, and system navigation.

Includes:

FANUC control interface layout

MDI, jog, home, and reference modes

Machine zero return (G28)

Feed rate, spindle control, and emergency stop

Simulation Practice:

Home return and toolpath jogging

Objective: Write structured programs using FANUC word address format.

Includes:

Program structure (O, N, G, X, Y, Z, F, S, T, M)

Header, body, and end blocks

Safety codes (G40, G49, G80, G90, G21, G17)

Sequencing and numbering

Simulation Practice:

Write and simulate a blank program for structure validation

Objective: Master movement and control commands for milling and turning.

Includes:

G00, G01, G02, G03, G17–G19, G20–G21

M03–M09, M30, M06 (spindle, coolant, and program control)

G90/G91 absolute/incremental modes

G94/G95 feed modes

Simulation Practice:

Linear vs circular interpolation path simulation

Objective: Learn how to set up work coordinates and tool offsets.

Includes:

Work offsets (G54–G59)

Tool length offsets (G43/G44/G49)

Cutter compensation (G40/G41/G42)

Speed (S) and feed (F) setup concepts

Simulation Practice:

Apply offsets and verify path corrections

Objective: Understand milling machine parts and basic setup.

Includes:

VMC & HMC construction

Tool holding and spindle orientation

Fixture setup and safety interlocks

Home reference (G28)

Simulation Practice:

Explore VMC machine layout and axis control

Objective: Write programs for milling operations and simulate part cutting.

Includes:

Side facing, chamfer cutting, pocketing, multi-pocket operations

G00, G01, G02, G03, G17, G18, G19

M98 (subprogram) and L (loop count)

Simulation Practice:

Multi-pass toolpath visualization and contour simulation

Objective: Learn and implement drilling and tapping operations.

Includes:

Canned cycles: G81, G83, G73, G85, G86, G84

Parameters: X, Y, Z, R, Q, P, F

Canned cycle cancellation (G80)

Simulation Practice:

Multi-hole drilling and tapping simulation

Objective: Develop modular, reusable programs for repetitive operations.

Includes:

Subprogram creation using M98 & M99

Looping with L counts

Modular workflow example: pocket repetition

Simulation Practice:

Create a reusable subprogram for repeated drill patterns

Objective: Combine multiple operations into one complete program.

Includes:

Advanced cycles: G76 fine boring, G80 cancel

Tool changes (M06 T01–T02)

Coolant simulation (M08, M09)

Simulation Practice:

Full part simulation: face → drill → pocket → chamfer

Objective: Apply all learned milling skills in one integrated project.

Includes:

Write and simulate full component program:

Facing → Drilling → Pocket → Chamfer → Radius operationValidate G/M code accuracy, subprogram logic, and tool offsets.

Objective: Learn lathe construction and coordinate system.

Includes:

HTC/VTC structures

Spindle axis (Z) and tool movement (X/Z)

Tool turret and offset settings

Lathe terminology: DOC, RPM, feed, OD, ID

Simulation Practice:

Observe coordinate direction and tool approach

Objective: Write basic lathe programs for facing and turning.

Includes:

G00, G01, G02, G03

Incremental coordinates (U/W method)

Tool offset numbering (T0101, T0202, etc.)

Spindle and coolant control (M03, M04, M09)

Simulation Practice:

Run facing and step turning simulation

Objective: Master multi-pass and complex cycle operations.

Includes:

G70 Finishing, G71 Roughing, G72 Facing, G73 Pattern Repeat

G74 Drilling, G75 Grooving, G76 Thread Cutting

Subprogram loops for repetitive patterns

Simulation Practice:

Rough + finish cycle simulation with threading

Objective: Apply offset and nose radius compensation logic.

Includes:

Tool offset logic and numbering

Tool nose radius adjustment

Work offset (G28 U0.0 W0.0)

Compensation error prevention

Simulation Practice:

Observe nose radius offset variation in simulation

Objective: Write and simulate a complete turning part program.

Includes:

Facing → Turning → Grooving → Threading → Drilling → Tapping

Apply subprogram calls

Validate final geometry and toolpath flow

Objective: Learn to identify, correct, and optimize CNC codes.

Includes:

Common alarms and error handling

Code verification and dry-run inspection

Cycle time reduction techniques

Code documentation standards

Simulation Practice:

Identify & fix syntax errors; compare before/after optimization

Objective: Demonstrate full understanding of both Milling & Lathe through integrated simulation.

Includes:

Complete project coding (Milling + Lathe)

Toolpath verification & feed optimization

Final report preparation with screenshots