CAM SOFTWARE

About Course

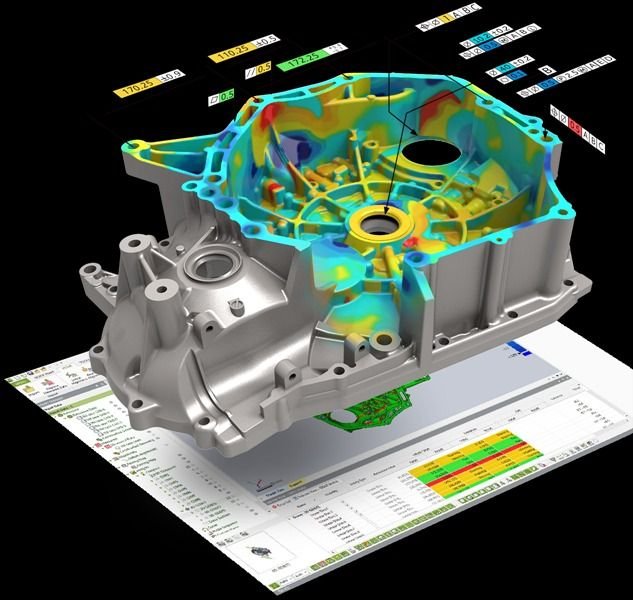

The Unigraphics NX (UG-NX) CAM program is an intensive, hands-on training course designed to help students master the complete digital manufacturing process — from 2D drafting and 3D product modeling to automated NC code generation and simulation.

This course bridges design and manufacturing, allowing students to experience how a product moves from concept to cutting, using the same advanced tools employed in modern CNC industries. It is a practical simulation-based program where students generate, verify, and optimize toolpaths without needing physical machines.

Course Objectives

Pre-requisites

This course is suitable for individuals with:

Basic understanding of CNC machining concepts (preferred)

Familiarity with 2D/3D CAD software (AutoCAD, CATIA, or SolidWorks)

No prior CAM experience required — all fundamentals are covered

Duration

Total Duration: 2 Months

1 Month of Intensive CAD Training

1 Month of NX CAM ProgrammingDaily Duration: 8 Hours per day

Class Recordings: Available for revision and practice

What You'll Learn

✅ Understanding complete CAD–CAM–CNC workflow

✅ 2D drafting and product modeling for manufacturing

✅ CAM environment setup and work coordinate creation

✅ Toolpath generation for 2.5D & 3D machining

✅ Automatic G-code/M-code generation using post processors

✅ Toolpath simulation, verification, and optimization

✅ Setup sheet, tool list, and process documentation creation

Who Can Join

Diploma & B.Tech Mechanical / Production / Industrial students

CNC or CAD-trained students looking to expand into CAM programming

Professionals seeking to upgrade to Unigraphics NX for manufacturing applications

Training Phase

Objective: Understand the CAD-to-CAM process and Unigraphics NX interface.

Topics:

What is CAM and its role in manufacturing

NX environment overview (Modeling, Manufacturing, Simulation)

CAD–CAM workflow: part → setup → toolpath → NC code → simulation

File formats and industry relevance

Lab: Explore NX workspace and load a sample CAM project.

Objective: Prepare 2D drawings and clean geometry for CAM operations.

Topics:

2D sketching, constraints, and profiles

Importing/cleaning DXF & DWG files

Creating contour sketches and defining boundaries

Lab: Draft a 2D part, clean geometry, and prepare for CAM.

Objective: Model CAM-ready parts and define machining stock.

Topics:

Solid/surface creation tools (extrude, revolve, fillet)

Datum planes and reference geometry

Defining workpiece, stock, and blank size

Lab: Model a simple component and define stock geometry.

Objective: Create machine coordinate systems and fixture setups.

Topics:

Work coordinate system (WCS) and orientation

Zero point selection, fixturing, and setup management

Stock alignment and safe tool clearance zones

Lab: Create a valid machine setup for a 3-axis part.

Objective: Manage tools and cutting data for accurate toolpath generation.

Topics:

Tool creation (end mills, drills, taps, etc.)

Feed, speed, depth, and step-over parameters

Tool length offset and tool life basics

Lab: Build a tool library and assign tools to operations.

Objective: Generate and edit toolpaths for different machining operations.

Topics:

Facing, pocketing, contouring, drilling cycles

Z-level roughing/finishing and freeform surface machining

Entry/exit moves and collision avoidance

Lab: Program a 2.5D and 3D part and simulate toolpath motion.

Objective: Generate machine-ready NC programs.

Topics:

Post-processor selection and customization

G-code/M-code review for different controllers

Header/footer format and dwell/coolant commands

Lab: Post-process CAM operations and inspect NC output.

Objective: Validate NC programs before production.

Topics:

Toolpath, material removal, and collision simulation

Machine envelope checks and tool/holder interference

Verification reports and error correction

Lab: Run simulation and verify stock removal accuracy.

Objective: Refine toolpaths and generate manufacturing documentation.

Topics:

Feed/speed tuning and strategy optimization

Generating setup sheets, tool lists, and operation reports

Process planning and time estimation

Lab: Optimize a toolpath for cycle time and output setup sheet.

Objective: Complete an end-to-end manufacturing simulation project.

Project Scope:

Model a part → Define setup → Create toolpaths → Generate NC → Verify simulation

Include facing, pocketing, drilling, and contour finishing operations.

Deliverables:

NC code, setup sheet, simulation screenshots, and short report.

Outcome: Students gain complete confidence in automated code generation and verification using NX CAM.